- hasivo@hasivo.com

- Mon - Sat at 7:00AM to 9:00PM

Leave Your Message

In the realm of industrial automation, the role of an Industrial Managed Switch cannot be overstated. These devices facilitate seamless communication across various networked devices. They ensure reliability and maintain connectivity in complex industrial environments.

Choosing the right Industrial Managed Switch is crucial. Many options exist, but not all are created equal. Features like redundancy, security, and ease of management play a significant role in this selection process. It’s important to understand the unique needs of your operations, as a mismatch can lead to serious setbacks.

Investing in the top Industrial Managed Switch options can significantly enhance network performance. However, careful consideration is needed. Each industrial setting is different, and what works for one may not work for another. Awareness of your specific requirements is vital for optimal implementation.

Industrial managed switches play a crucial role in network performance. They are designed for tough environments often found in factories and manufacturing facilities. Unlike standard switches, they can handle extreme temperatures and vibrations. This durability makes them essential in industrial settings.

These switches offer advanced features like VLAN support and traffic management. They help prioritize critical data, ensuring smooth operations. In addition, they offer greater control over network security. For industries relying heavily on data, this is vital. Many organizations are shifting to managed switches for their scalability and reliability.

**Tip:** Always check the environmental ratings before purchasing. Not all switches can withstand harsh conditions.

Configuration can be complex. It requires knowledge of networking protocols. This can be daunting for some. Mistakes may lead to network downtime.

**Tip:** Consider investing in training for your team. A well-informed staff can optimize switch performance.

Another aspect is maintenance. Regular checks are necessary to ensure optimal function. Neglecting this can cause unforeseen issues.

**Tip:** Set up alerts for monitoring potential failures. It can save time and resources in the long run.

| Model | Port Configuration | Maximum Throughput | Management Type | Operating Temperature Range |

|---|---|---|---|---|

| Industrial Switch A | 8 x 10/100/1000 Mbps | 20 Gbps | Fully Managed | -40 to 75 °C |

| Industrial Switch B | 16 x 10/100 Mbps, 2 x SFP | 8 Gbps | Web Managed | -40 to 85 °C |

| Industrial Switch C | 24 x 10/100/1000 Mbps | 48 Gbps | Layer 2 Managed | -40 to 70 °C |

| Industrial Switch D | 10 x 10/100/1000 Mbps | 10 Gbps | Smart Managed | -40 to 80 °C |

| Industrial Switch E | 6 x 10/100 Mbps, 4 x Fiber | 6 Gbps | Unmanaged | -40 to 75 °C |

When selecting industrial managed switches, several key features play a crucial role in performance and reliability. Look for switches that offer robust security protocols. According to reports, 75% of industrial networks are vulnerable without proper cybersecurity measures. Secure features can help mitigate risks.

Reliability is essential. An ideal switch should have a high Mean Time Between Failures (MTBF) rating. Research shows that industrial environments often face harsh conditions. Therefore, switches that can withstand extreme temperatures and vibrations are invaluable. A switch designed for these environments often lasts longer, offering better ROI over time.

**Tip:** When considering features, prioritize redundancy options. This can prevent network failure due to a single point of failure. Additionally, power over Ethernet (PoE) support can simplify device connectivity, especially in areas with limited power availability. Keep in mind that not all switches support all these features, so careful consideration is vital.

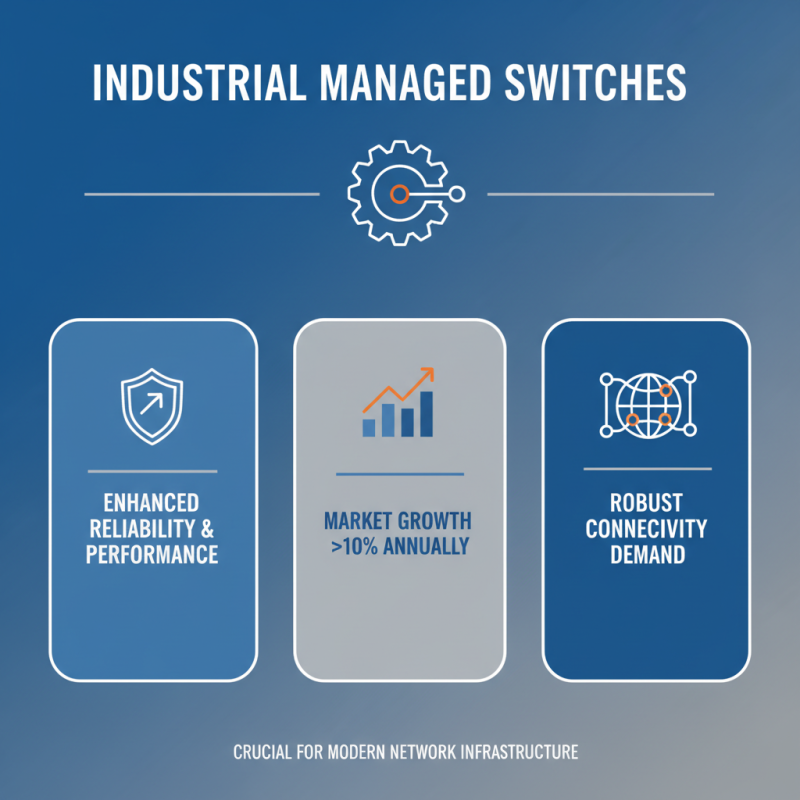

Industrial managed switches are crucial in modern network infrastructure. They provide advanced features that enhance performance and reliability. According to a recent market report, the industrial switch market is expected to grow by over 10% annually, reflecting the increasing demand for robust connectivity solutions.

Key aspects include redundancy features and security protocols. Some models support rapid ring recovery and power over Ethernet. They help maintain uptime in critical environments, which is vital for operations. However, not all switches handle harsh conditions effectively. Some users have found durability issues in extreme temperatures. This reflects a need for careful selection.

Another factor to consider is management capabilities. The ability to configure settings remotely can save time and resources. Yet, complexity may arise in user interfaces. Some employees struggle to navigate these settings, which can lead to configuration errors. Choosing the right switch requires balancing ease of use with feature sets. It is worth noting that ongoing training is essential.

Choosing the right industrial managed switch can be a challenging task. Performance and reliability are key factors. Some switches handle heavy data loads better than others. Others excel in terms of uptime and durability.

Certain switches have higher throughput rates. This means they can process more data simultaneously. However, higher performance often comes with increased costs. It’s important to weigh these factors against your specific needs. Reliability matters too. In critical environments, even one failure can be costly.

Look for switches with redundancy features. These help prevent downtime. Pay attention to environmental ratings as well. Some switches are rated for extreme temperatures and harsh conditions. Not all switches can handle these environments equally. Some may struggle, leading to potential failures. Always consider the trade-offs. Balancing performance, reliability, and costs will help you choose the right switch.

Choosing the right industrial managed switch can be challenging. Factors like scalability, reliability, and ruggedness are crucial. According to a recent industry report, over 40% of network failures are linked to inadequate switch selection. This emphasizes the importance of thorough evaluation.

When selecting a switch, consider the environment where it will operate. Many industrial settings expose equipment to extremes. The right switch should withstand temperature fluctuations and moisture. A study indicates that 22% of network downtime comes from equipment failures in harsh environments. Look for devices with robust enclosures and certified ratings for such situations.

Network size is another critical aspect. A switch that fits a small operation may not scale well. Research shows that nearly 60% of businesses experience growth-related network issues. Therefore, investing in a scalable solution is vital. Think of your future needs. Will the switch adapt as your operations expand? Engaging with your network's specific demands will lead to better long-term decisions.